FACES OF FREIGHT – The Signal – 8/28/25

From dispatchers to engineers, trainers to locomotive shop managers—freight railroaders connect farms to tables, factories to markets, and communities nationwide. The careers they build—long-lasting and often passed down through generations—stand as some of the very best in the nation:

- Stability: The average railroader stays on the job 14 years—triple the national average.

- Rewarding pay: Class I rail employees earn $135K to nearly $190K in total pay and benefits each year.

- Safety first: Freight rail is among the safest industries in America—with injury rates lower than grocery stores.

Below are quotes from just a few freight railroaders we recently had the pleasure of speaking with. Their real, unfettered stories of how they started in rail, why they stay and how they feel about their jobs left us inspired. We’ve been looking forward to sending this edition of The Signal!

Happy Labor Day Weekend,

The Signal Team

Santricia has been with BNSF for more than 13 years as a Conductor and recently has been working in the yard tower to help keep trains smoothly moving through an intermodal facility right outside Chicago.

“I go to sleep thinking about the railroad. I wake up thinking about the railroad. Even on my off days, I’m thinking about my job. I love it…I have grown. This job has opened the door to things I just didn’t even know at the time 13 years ago. There is still a lot of opportunity to grow.”

Joe D. has been a Train Master with CPKC for seven years, having worked his way up from a Ground Conductor.

“My job is to drive safety and be efficient. I put trains together that move the nation’s freight. I just love coming to work and playing Tetris, putting the pieces together. It’s like a puzzle.

I used to work in concrete, but CPKC offered something better for me, for my family, for retirement. It’s a great job with great benefits. It’s just an overall life changing experience coming to freight rail.”

At Norfolk Southern, Danny M. serves as a Locomotive Shop General Supervisor, overseeing inspections and ensuring every locomotive is ready for a safe journey.

“I’ve been here 16 years and I take our commitment very seriously. It’s not just a priority, it’s a value. Every time an engine comes out of this shop, it’s a success for us because that means it is safe and ready to go to its final destination.”

Sam G., a Technical Trainer at Canadian National, onboards and recertifies Signal and Communication Technicians. He guides the next generation of railroaders through classroom and field training, covering everything from electrical basics to the technologies that keep employees and the network safe.

“Take for example a Hot Box. We really take the time to explain the workings, the components, and how it works on the mainline. And this is all part of our safety culture. We don’t just talk about it. We live it.

Everything innovative in my industry excites me—seeing the shift to a proactive, autonomous environment is incredible. The more technology we implement, the more efficient and safer we become, and the easier it is to identify and resolve issues proactively instead of reactively.”

( A hot box, aka a hot bearing detector, uses infrared sensors to measure the temperature of wheel bearings as trains pass by)

A hot box, aka a hot bearing detector, uses infrared sensors to measure the temperature of wheel bearings as trains pass by)

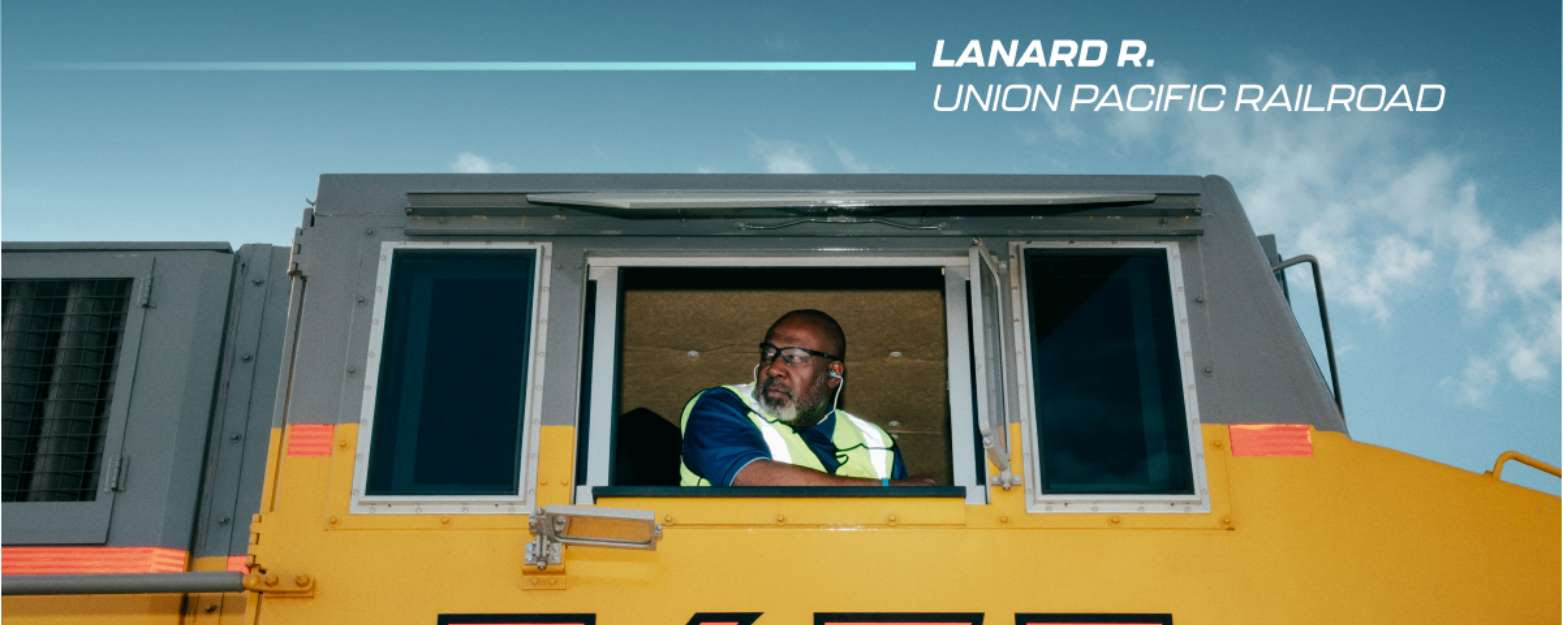

With 25 years as a railroader under his belt, Union Pacific Train Engineer Lanard R. plays a vital role in keeping America’s supply chains moving.

“The goods that you use every day? The stuff that you go to the store to buy? I’m the individual that delivers those goods so you have what you need at home, at work and for your day-to-day life. We are interstate commerce, and I take that responsibility very seriously. Rain or shine, my goal is to deliver America’s freight as safely and efficiently as possible.”

(When Lanard showed us the cab of his locomotive, he proudly referred to it as his office. )

)

For the past decade, Brett G. has managed projects for CSX’s Design & Construction Group as part of the Chicago Regional Environmental & Transportation Efficiency (CREATE) Program, which uses innovative engineering to ease Chicago’s rail and road bottlenecks—improving safety, efficiency, and reliability at the nation’s busiest rail hub. She’s been with CSX for a total of 15 years.

“If you would have asked me in middle school what I wanted to be, I probably would have said a hairstylist. But a couple of years into high school, my guidance counselor suggested I attend a Women in Engineering seminar and so I went and was introduced to engineering of all kinds.

There are so many engineers that all they ever see is the paper. But with my job, I not only get to talk about the idea and have input into the design for the plans that the contractors will eventually use to build it, I also get to see it built.”